JFX200-2513 EX

Industry leading large flatbed UV-LED printer

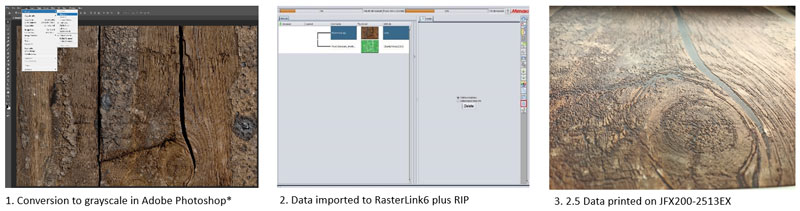

Building on the success of the JFX200-2513, the new JFX200-2513 EX defines the next-generation in large flatbed LED UV printing. Thanks to our new 3D print technology, the JFX200-2513 EX introduces 2.5D layered printing where our RIP Rasterlink6 PLUS automatically creates up to 17 layers based on just one grey-scale image. Each gradation layer is processed differently, creating an amazing realistic depth with varied layer thicknesses on the printed media, resulting in seamless beautiful textures. With a high speed mode of 35m2/h, the newly designed staggered heads carriage allow simultaneous print of colour and white.

|

|

|

|

|

|

Create…

The range of possible applications is practically limitless. A selection:

Art reproduction, Backlit graphics, Construction signs, Displays, Exhibition signs, Rigid packaging, Lenticular (printing with 3D effects), ID cards, Logos (3D), Operation panels, Promotional items, Relational gifts, Accessories and much more…

Substrates

The Mimaki JFX200-2513 EX can print on an extensive range of materials, such as: Acrylics, Polycarbonates, PVC, Glass, Aluminium, Metal, Polyester, Foam board, Styrene, Wood, Stone

Attention should be paid to ink adhesion. Even though our colour inks will print onto almost any substrate, levels of adhesion do differ between materials. Our primer PR-200 ink improves the adhesion, whilst retaining the look and feel of the media.

Specifications of JFX200-2513 EX

| Item | JFX200-2513 EX | |

| Head | Staggered array of 3 heads | |

| Print resolution | 300, 450, 600, 900, 1,200dpi | |

| Ink | Type | LED UV Curable Ink: LH-100, LUS-120, Primer: PR-200*2 |

| Supply system | 1 litre / 250ml bottles (LH-100, LUS-120, PR-200 only)*3 | |

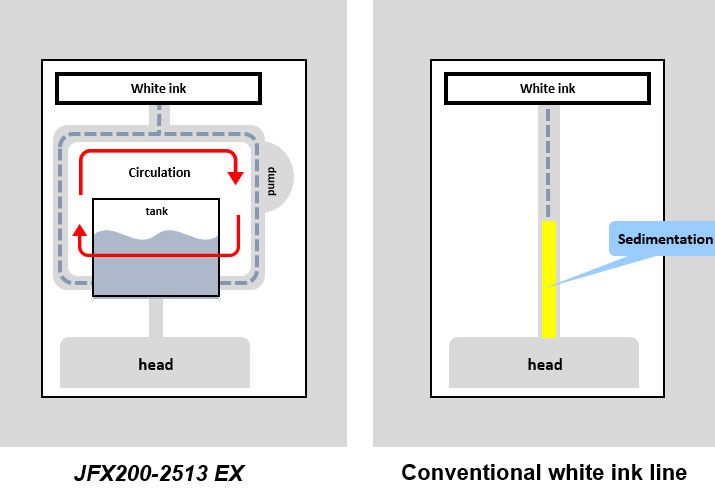

| Circulation | White ink circulation system using Mimaki Circulation Technology (MCT)*4 | |

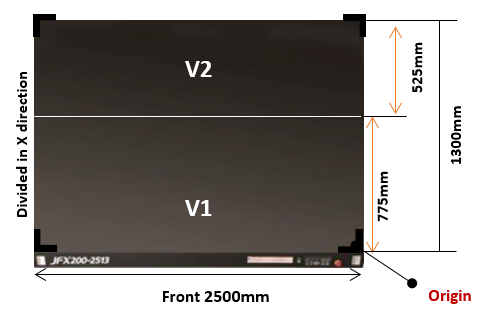

| Maximum printable area | 2,500 × 1,300mm | |

| Media | Dimensions | 2,500 × 1,300mm |

| Height | 50mm | |

| Weight | 50 kg/m2 non concentrated load | |

| Media absorption | Vacuum type | Absorption fixed through use of a vacuum |

| Vacuum zones | 2 partitions (X-axis direction) | |

| UV device | System | LED-UV system |

| Service life | Over 5,000 hours*5 | |

| Interface | USB2.0 + Ethernet connection | |

| Safety standard | VCCI class A, CE Marking, CB Report, UL (U.S. safety organisation), RoHS directive, UL 60950-1, FCC class A | |

| Power | Supply | Single phase, 200V AC-240V AC, 50Hz/60Hz, < 12A |

| Consumption | < 2.88kVA | |

| Installation environment | Temp: 15°C-30°C | Humidity: 35%-65% RH | |

| Dimensions (W×D×H) | 4,400 × 2,450 × 1,250mm | |

| Weight | 650kg | |

Mimaki LED-UV inks LH-100, LUS-120 and LUS-150 are GREENGUARD Gold certified.

Features of JFX200-2513 EX

Building on the success of the JFX200-2513, the new JFX200-2513 EX defines the next-generation in large flatbed LED UV printing. Thanks to our new 3D print technology, the JFX200-2513 EX introduces 2.5D layered printing where our RIP Rasterlink6 PLUS automatically creates up to 17 layers based on just one grey-scale image. Each gradation layer is processed differently, creating an amazing realistic depth with varied layer thicknesses on the printed media, resulting in seamless beautiful textures. With a high speed mode of 35m2/h, the newly designed staggered heads carriage allow simultaneous print of colour and white.

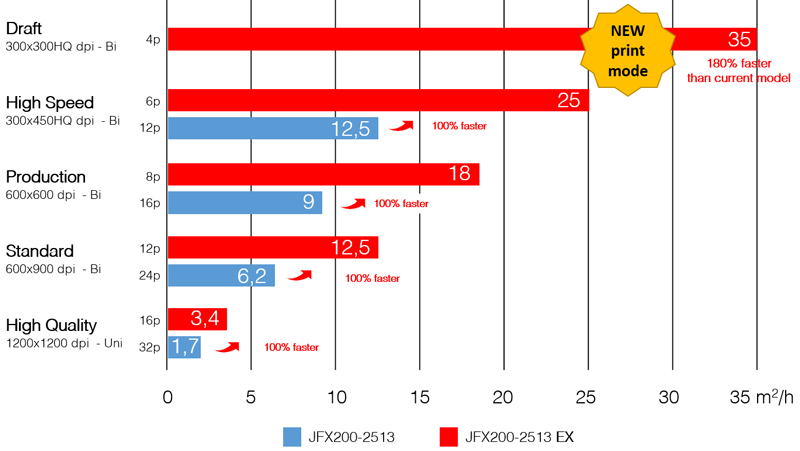

Print speed

Compared to the JFX200-2513:

- Print speed is twice as fast at every print mode

- Plus, the JFX-2513 EX introduces a new high speed print mode of 35sqm/h

New 2.5D printing technology

Easy 2.5D creations are now possible in just a few clicks for everyone using the RasterLink6 PLUS RIP

- Forms relief texture on any print material

- Bridges the gap between 2D and 3D applications

Improved usability

Foot switch

- A foot pedal is installed at the front of the printer for easy turning ON/OFF the vacuum power without having to access the control panels

- Vacuum units can be switched on/off via the control panel

- Vacuum area is divided in X direction and can be set depending on the media size

- Optional stronger vacuum unit also available

Ethernet connection

- In addition to the USB2.0 connection, an Ethernet connection is also available on the new JFX200-2513 EX

- It provides convenience by allowing to connect several printers with only one computer

- Installation is done simply by plugging cables into the network

Event email

- For remote status indication of the printer, the printer status can be sent from the printer to a PC or mobile phone via the Internet

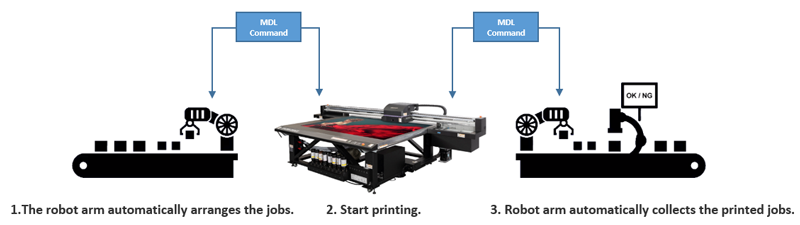

IOT automation

- MDL commands* are used to embed Mimaki printers with the unattended on-demand production lines from customer production systems and peripheral equipment, enabling easy integration with automation systems on the production floor

- Utilisation of the MDL commands controls the position and height of the print head and the operation of the printer, such as the start of printing

External safety I/F

- In addition to the standard emergency switch, an external safety I/F allows for the external connection of a wide variety of safety applications* such as safety light curtains, etc.

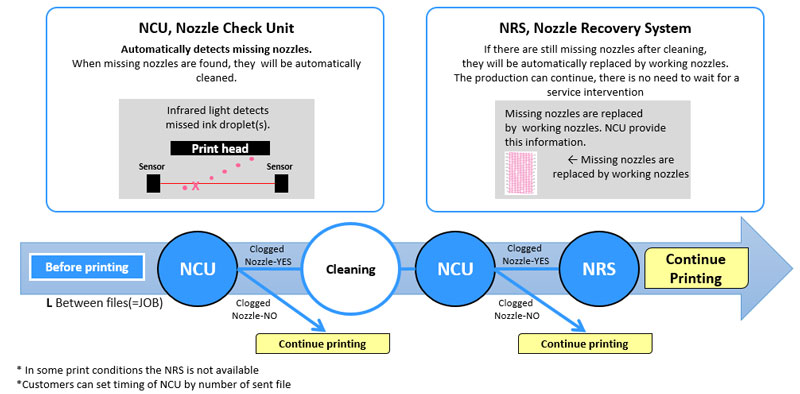

Enhanced uninterrupted printing

Non-stop printing with automatic maintenance

- NCU (Nozzle Check Unit) automatically checks the nozzle condition

- When missing nozzles are detected, they will be automatically cleaned

- If still missing after cleaning, the NRS (Nozzle Recovery System) will automatically replace with working nozzles, so there is no need to wait for a service intervention

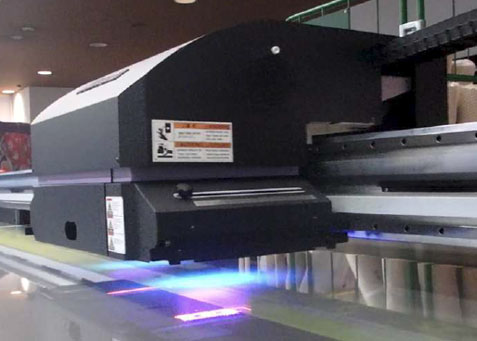

Advanced LED-UV curing unit

150% higher luminance

- In comparison to previous models, the newly designed LED-UV unit provides up to 150% higher luminance levels

- It results in an even more stable and faster curing of LED UV inks

Less VOC

- Little VOC (volatile organic compound), no ozone production

- With less odour, no special “expensive” ventilation systems are required

Energy efficient

- Generates less heat and turns on only when needed

- Less power consumption, therefore reduced running costs

Less heat impact

- With low temperature LED-UV lamps, the temperature does not exceed 30⁰C, enabling prints on cheaper and heat sensitive media, as well as media deformation (often caused by metal halide lamps which reach temperatures up to 70⁰C)

Less downtime

- Long-life LED-UV lamps require less maintenance

- The lifetime of LED-UV lamps is approx. 5000 hours (lifetime of metal halide lamps is approx. 350-700 hours)

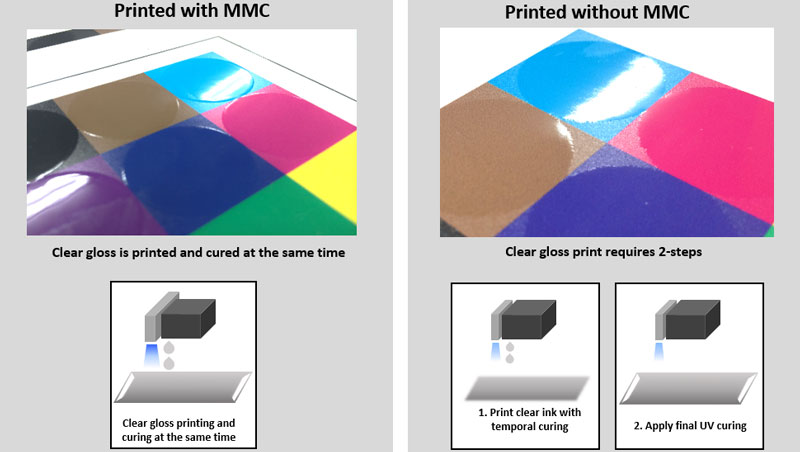

MCC (Mimaki Clear Control)

Beautiful clear ink printing

- Using MCC, a high quality gloss finish is achieved due to greater image quality control and less dust attachment

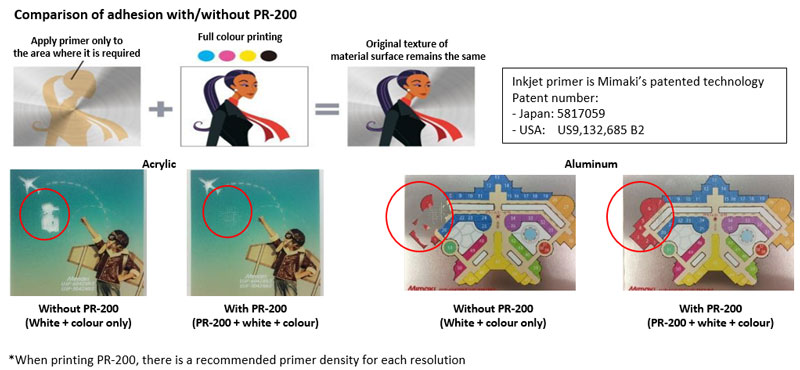

LED-UV primer

Primer PR-200

- PR-200 dramatically improves the adhesion when printing with colour inks

- Primer can be applied to the area where it is needed

- Effective and economical use of primer retains look and feel of the media

MCT: Mimaki Circulation System

- Prevents settlement of white ink pigments

- Ensures a constant optimal ink supply

- Reduces the amount of waste ink

- MCT works only when the white ink set is installed

Image quality control

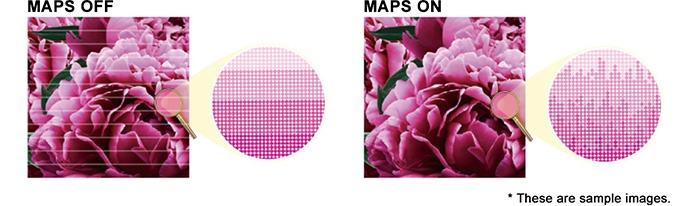

MAPS (Mimaki Advanced Pass System) for printing without banding

- MAPS eliminates banding by dispersing ink drops between the passes

- This technology improves the print quality when printing in high productivity modes, and reduces uneven print density of solid colour areas

- By printing in auto-mode in MAPS, the condition of MAPS is automatically selected for each print mode

- Using MAPS does not change the print speed

- The optimum setting condition varies depending on print data or media. Be sure to test the image quality beforehand

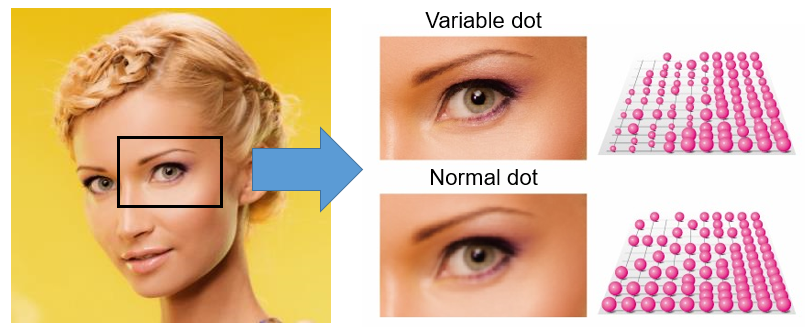

Variable Dot Technology: reduces grainy appearance

- Variable Dot Technology enables the printer to print in 3 different dot sizes (small, medium and large) to create high quality images with smooth gradations

- Variable Dot Printing uses smaller drops to produce smoother gradations, while bigger drops create uniform solid colours

- By producing dots in three different sizes, high resolution graphics are created without a grainy appearance, even at high speed and in low resolution mode

Waveform Control to achieve precise placement of ink droplets

- The dots are optimized by tuning the frequency depending on ink’s viscosity to accurately place and shape individual ink droplets

- This results in sharper lines, text and optimized image even at lower resolution

Mimaki LED-UV inks LH-100, LUS-120 and LUS-150 are GREENGUARD Gold certified.